Chemical Cleaning Services

GPPS offers both facility post- construction and maintenance chemical cleaning services to the oil and gas facilities.

Post construction chemical cleaning is done as part of facility pre-commissioning services, before it is put into service. This is performed to remove any extraneous or foreign materials that may have remained in the system after construction activities had been completed. The materials include mill scale, rust, sand, oil, grease and other debris that might have negative effects on the system when put into service.

Maintenance chemical cleaning is done during facility planned maintenance during shut down. This is performed to improve flow assurance, reduce heat transfer issues and for access for regulatory or ad hoc internal inspection.

Our methodology of chemical cleaning include filling the system with the desired chemical solution and then using a pump to circulate the solution within the system for a designated period, while testing for system for internal cleanliness at regular intervals. This is normally done to clean the internals of vessels and piping with large volumes.

Another methodology employed by GPPS is the fill and soak method. This is normally done when the filling and circulating methodology is not practicable. In this method, the system is filled with the desired chemical solution and allowed to soak for a designated period. After the system has been adequately soaked, the solution is drained. This process may be repeated until the system internal is clean. Usually heat is applied to the solution to recommended temperature in 0C before filling the system.

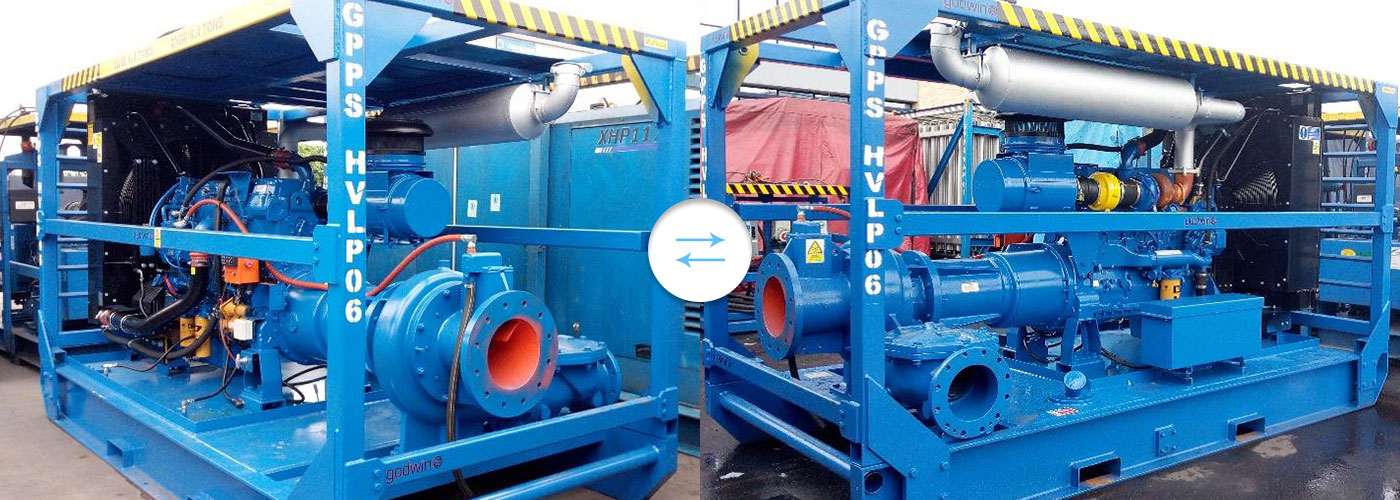

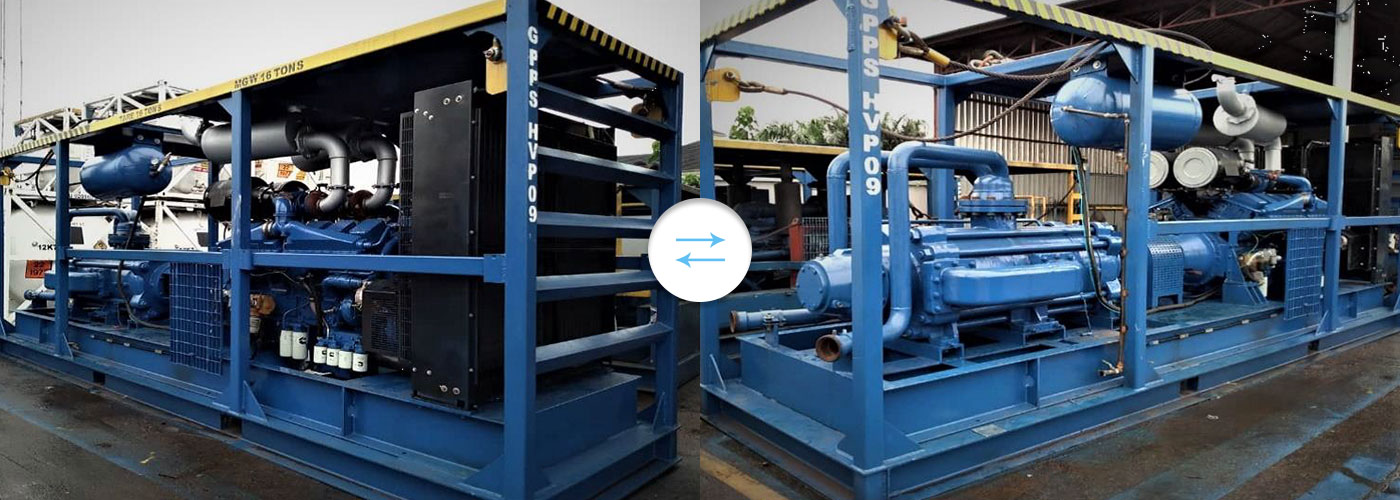

GPPS has a fleet chemical cleaning equipment which includes high-volume fill and circulating pumps with flow regimes from ( 439 – 1,224 m3/hr), 310 bbls stainless steel tanks with heating capability up to 900C, 200 – 250 bbls stainless steel containment tanks, high pressure chemical cleaning hoses, filtration units, and high reliability testing equipment.